Polymer composite film heat sealing equipment

1. Equipment classification and working principle

1. Classification by heat sealing method

Constant temperature heat sealer

Principle: Directly press the film material through the upper and lower heating plates, suitable for sealing of flat or simple shapes.

Features: Simple structure, low cost, suitable for small batch production.

Application: Food bags, aluminum-plastic blister packaging of medicines.

High frequency heat sealer

Principle: Use high-frequency electromagnetic field to make the internal molecules of the film material vibrate to generate heat, and achieve contactless sealing.

Features: Fast sealing speed, suitable for thick film or composite film containing aluminum foil.

Application: Medical infusion bags, waterproof breathable film.

2. Classification by degree of automation

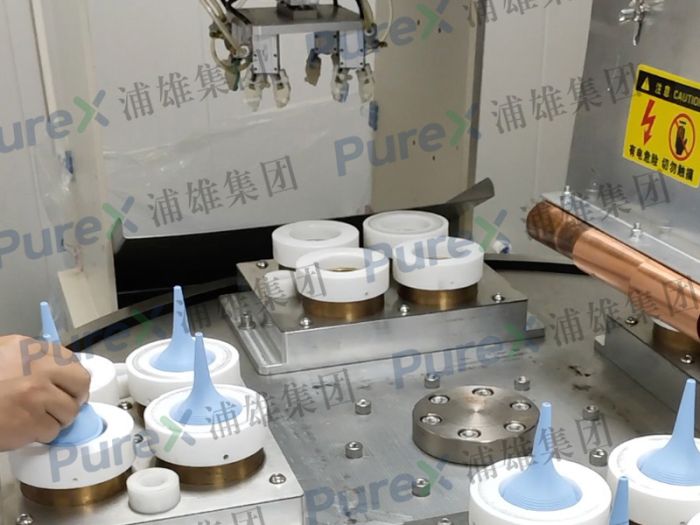

Manual/semi-automatic equipment: Suitable for laboratory or small-scale production, flexible operation but low efficiency.

Fully automatic production line: Integrated feeding, heat sealing, cutting, detection and other functions, suitable for industrial production.