Precision Medicine: Optimization and Practice of Heat Sealing Connection Technology for Disposable Blood Transfusion Sets

1. Importance of heat-sealing connection process

As an indispensable device in the medical process, the heat-sealing connection part of the disposable blood transfusion set needs to withstand the pressure of blood flow and maintain a sterile state to prevent infection. Therefore, the quality of the heat-sealing connection process directly determines the sealing, strength and sterility of the blood transfusion set, and is an important barrier to ensure the safety of blood transfusion.

2. Optimization of heat-sealing connection process

Material selection and pretreatment

Material selection: Select medical-grade polymer materials that meet the standards of medical devices, such as polypropylene (PP), polyethylene (PE), etc. These materials have good biocompatibility, chemical resistance and aging resistance.

Pretreatment: Strictly pretreat the materials, including cutting, cleaning, drying and other steps to ensure the flatness and cleanliness of the connection surface and reduce the impact of impurities on the connection quality.

Process parameter optimization

Heating temperature and time: Through repeated experiments and data analysis, determine the optimal heating temperature and time range to ensure that the material can achieve good fluidity during the melting process and avoid deformation or burning caused by overheating.

Pressure control: During the lamination process, the applied pressure is precisely controlled to ensure that the molten material is fully diffused on the joint interface and forms a strong connection. At the same time, avoid excessive pressure that causes material extrusion or damage.

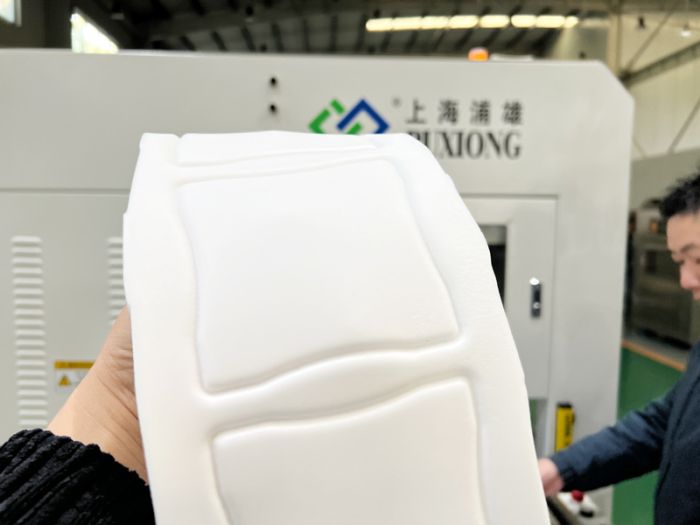

Equipment upgrade and automation

Introduce advanced heat sealing equipment, such as high-frequency heat sealing machines or blood aseptic heat sealing machines, which can more accurately control parameters such as heating temperature, time and pressure, and improve the accuracy and efficiency of heat sealing connections.

Realize automated production and reduce the impact of human factors on product quality. Through the automated control system, each link in the production process is monitored and adjusted in real time to ensure the stability and consistency of product quality.

Quality inspection and monitoring

Establish a complete quality inspection system and conduct strict quality inspection on the components after heat sealing. Including sealing test, strength test, etc., to ensure that the connection quality meets the standard requirements.

Implement an online monitoring and traceability system to record and monitor the key parameters in the production process in real time, so that the cause can be quickly traced and measures can be taken to solve the problem when it occurs.

III. Practical cases and effects

In actual production, many medical device manufacturers have successfully applied the optimized heat sealing connection process to the production of disposable blood transfusion devices. Through the implementation of measures such as material selection, process parameter optimization, equipment upgrade and automated production, not only the sealing, strength and sterility of the product are improved, but also the production cost and defective product rate are significantly reduced. At the same time, these optimization measures also provide patients with safer and more reliable blood transfusion protection.

IV. Future Outlook

With the continuous advancement of medical technology and the continuous improvement of patient needs, the optimization and practice of the heat-sealing connection process of disposable blood transfusion sets will continue to deepen. In the future, we can expect the emergence of more new materials, new processes and new equipment to bring more innovations and improvements to the heat-sealing connection process. At the same time, we will strengthen interdisciplinary cooperation and the combination of industry, academia and research, promote the continuous upgrading and iteration of heat-sealing connection technology, and contribute more to the development of precision medicine.

.jpg)