The materials, structure and heat sealing welding of negative pressure drainage bottles

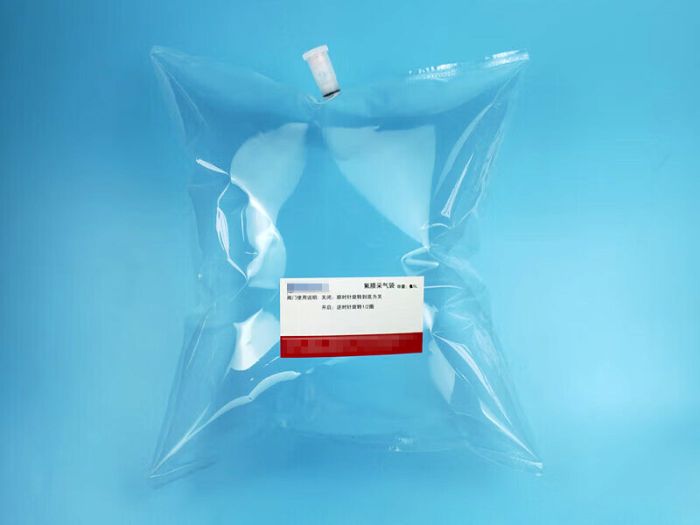

I. Materials and Structure of Negative Pressure Drainage Bottles

The body of a negative pressure drainage bottle is typically made of medical-grade plastic materials, such as polyvinyl chloride (PVC). This material offers excellent toughness and transparency, allowing medical staff to easily observe the color, properties, and volume of the drained fluid. The bottle's connectors are designed to match the outer diameter of drainage tubes and feature anti-slip grooves or locking slots to ensure secure connections. The bottle body is usually rigid plastic with strong sealing properties to prevent leakage.

II. Application of High-Frequency (HF) Thermal Fusion Welding in Negative Pressure Drainage Bottle Production

High-frequency thermal fusion welding is a critical process in the production of negative pressure drainage bottles, particularly for bonding PVC and other plastic materials. Its principle involves generating heat through molecular oscillation within the plastic material under a high-frequency electromagnetic field, enabling material fusion. HF welding offers the following advantages:

- Efficient Bonding: High-frequency fields rapidly polarize plastic molecules to generate heat, ensuring fast and efficient welding.

- Strong Sealing: Welded joints exhibit excellent airtightness, preventing leakage to meet medical requirements.

- Broad Applicability: Suitable for pure PVC or blends containing ≥30% PVC, meeting material specifications for drainage bottles.

III. Key Parameters of HF Thermal Fusion Welding Process

Equipment Requirements:

High-frequency plastic welding machines (HF generators) with oscillation frequencies of 27.12 MHz or 40.68 MHz (aligned with international industrial standards) must include:

- Spark Protection: Prevents damage to molds and materials.

- Temperature Control: Adjustable thermostat (0–300°C) for consistent weld quality.

- Pressure Adjustment: Customizable pressure based on material thickness for optimal fusion.

Workflow:

- Material Preparation: Align PVC bottle components and connectors in the welding mold.

- Parameter Setup: Configure HF output power, welding duration, and pressure based on material thickness and specifications.

- Welding Operation: Activate the HF field to generate molecular heat for fusion.

- Quality Inspection: Verify joint sealing integrity to ensure no leakage post-welding.

Quality Control:

- Weld Strength: Joints must withstand specified tensile and compressive forces during use.

- Visual Inspection: Welded surfaces must be smooth, free of bubbles/burns, and meet medical product standards.

IV. Advantages of HF Thermal Fusion Welding

- High Yield Rate: Mature technology ensures a 99.99% success rate, ideal for mass production.

- User-Friendly Operation: High automation reduces training requirements.

- Low Maintenance: Simple device structure and cost-effective upkeep for sustained production.

.jpg)