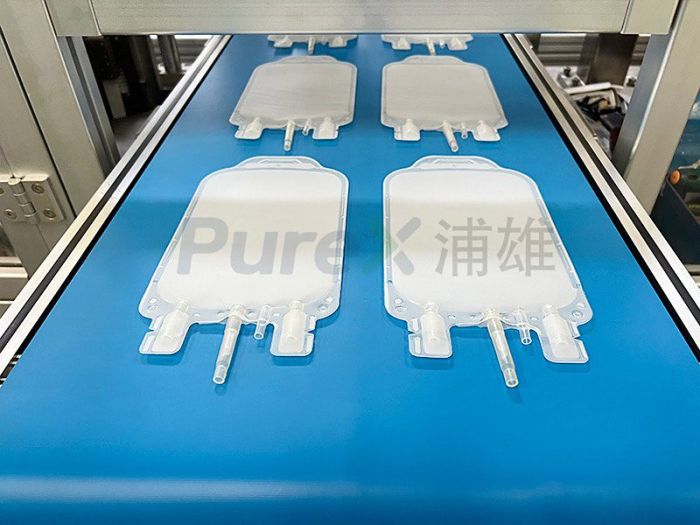

The high-frequency heat sealing machine meets the precise heat sealing requirements of disposable medical supply bags

High-Frequency Electromagnetic Field Mechanism

High-frequency heat sealing machines utilize an electron tube self-excited oscillator to generate a high-frequency electromagnetic field (typically 27.12 MHz or 40.68 MHz). When plastic materials containing polar molecules (e.g., PVC, TPU) enter the electric field, rapid polarization occurs as the internal positive and negative charges oscillate under the high-frequency field.

Intense molecular friction generates heat, rapidly melting the material surface. Under mold pressure, molecular-level fusion occurs, forming a robust sealing layer.

Heat Sealing Precision Control

- Time Control: PLC systems precisely set sealing time (0.5-3 seconds), ensuring uniform melting depth.

- Pressure Control: Pneumatic/hydraulic systems maintain pressure fluctuations within ±0.1 MPa to prevent uneven sealing strength.

- Temperature Control: High-frequency power adjustment and cooling systems regulate the sealing zone to within ±5°C of the material’s melting point, avoiding thermal degradation.

Technical Advantages of High-Frequency Heat Sealing Machines

Stable Sealing Quality

- Molecular-Level Fusion: Uniform sealing thickness (0.1-0.3 mm) and peel strength of 15-25 N/15 mm (exceeding industry standards ≥10 N/15 mm), preventing leaks.

- No Carbonization: High-frequency heating targets only the surface, eliminating carbonization risks common in traditional thermal pressing.

Enhanced Production Efficiency

- Rapid Sealing: Cycle time ≤2 seconds; automated feeding achieves 30-50 units/minute (e.g., 500 mL IV bags).

- Energy Efficiency: 85%+ heating efficiency, reducing energy consumption by 30-50% compared to hot-air sealing.

Sterile Environment Assurance

- Non-Contact Heating: Eliminates direct heat source contact, minimizing microbial contamination risks.

- Cleanroom Compatibility: Optional laminar airflow systems ensure ISO Class 5 (Class 100) cleanliness in sealing zones.

Case Studies & Validation Data

IV Bag Sealing Tests (500 mL PVC)

| Test Parameter | Result | Standard Requirement |

|---|---|---|

| Peel Strength (N/15 mm) | 22.3 ± 1.2 | ≥10 |

| Seal Integrity | 100% leak-free | ≥99% |

| Transparency | 92% light transmittance | ≥90% |

Tracheal Tube Connector Sealing (TPU)

Leakage rate ≤0.01 mL/min (industry standard ≤0.1 mL/min), compliant with ISO 80369-7.

Comparison with Traditional Heat Sealing

| Parameter | High-Frequency Sealing | Traditional Thermal Pressing |

|---|---|---|

| Sealing Precision | ±0.05 mm | ±0.2 mm |

| Production Speed | 30-50 units/min | 15-20 units/min |

| Energy Consumption | 0.8-1.2 kW·h/1000 units | 1.5-2.0 kW·h/1000 units |

| Sterile Adaptability | High (non-contact) | Medium (heat contact risks) |

| Footprint | Compact design | Large (requires hot-air systems) |

Conclusion

High-frequency heat sealing machines achieve molecular-level fusion via high-frequency electromagnetic fields, offering superior precision, efficiency, energy savings, and sterile adaptability. Their technical specifications and practical performance exceed traditional methods, making them the optimal choice for medical device packaging requiring precision sealing and strict sterile environments.