What types of fluorine material gas collection bags are there

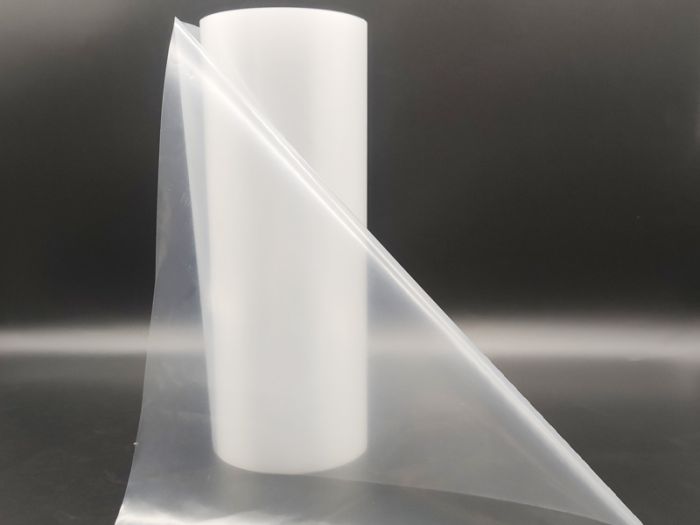

Fluoropolymer gas sampling bags are specialized containers designed for collecting, storing, and transporting gases. Their core material consists of fluorinated polymers, offering exceptional chemical stability, corrosion resistance, high-temperature tolerance, and low gas permeability. These bags are widely used in environmental monitoring, industrial analysis, scientific research, and laboratory applications. Below is an introduction to the primary types of fluoropolymer gas sampling bags:

.jpg)

Primary Types of Fluoropolymer Gas Sampling Bags

Based on material composition and applications, fluoropolymer gas sampling bags can be categorized as follows:

1. Polytetrafluoroethylene (PTFE) Gas Sampling Bags

Features: PTFE is the most widely used fluoropolymer material, characterized by an extremely low surface energy (non-stick properties), resistance to strong acids/alkalis, high-temperature tolerance (long-term use up to 260°C), and ultra-low gas permeability.

Applications: Ideal for collecting corrosive gases (e.g., Cl₂, H₂S), high-temperature gases, or samples requiring extended storage.

2. Fluorinated Ethylene Propylene (FEP) Gas Sampling Bags

Features: FEP, a modified form of PTFE, offers high transparency, flexibility, and chemical resistance comparable to PTFE, though with slightly lower thermal stability (long-term use up to ~200°C).

Applications: Suitable for scenarios requiring visual observation of gas color or transparency, such as photochemical reaction gas sampling.

3. Polyvinylidene Fluoride (PVDF) Gas Sampling Bags

Features: PVDF exhibits high mechanical strength, excellent abrasion resistance, and moderate flexibility, but its chemical resistance is slightly inferior to PTFE and FEP.

Applications: Recommended for moderately corrosive gas collection or situations requiring frequent bag opening/closing.

4. Ethylene Tetrafluoroethylene (ETFE) Gas Sampling Bags

Features: ETFE combines the chemical resistance of fluoropolymers with the flexibility of polyethylene, offering high transparency and lightweight properties.

Applications: Preferred for lightweight portable gas sampling devices.

5. Modified Fluoropolymer Blends

Examples include PTFE-glass fiber composites, which enhance mechanical strength and pressure resistance for specialized applications.