The TPU heat sealing process of the hand massage device

The TPU heat-sealing process of hand massagers is mainly reflected in the design and manufacturing of their double-layer TPU airbag structure, ensuring the product's durability and comfort. The following is a detailed analysis:

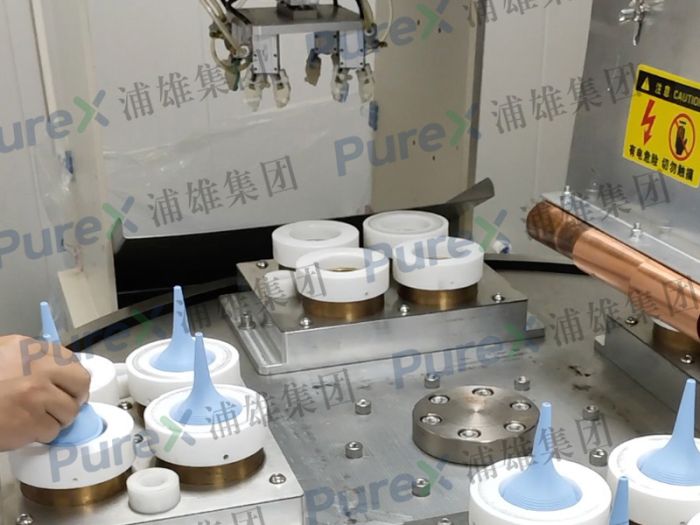

1. Precise Heat-Sealing Process of TPU Airbags

Separate Finger Structure: Utilizing 8 independently controlled airbags, precise fit is achieved across three main areas: fingers, palm, and wrist, through TPU hot melt adhesive bonding technology. This process requires precise temperature control between 90-130℃ to ensure complete adhesive melting without damaging the materials.

Double-Layer TPU Wrapping: The outer layer is a food-grade, skin-friendly fabric, and the inner layer is a TPU airbag, bonded together through a hot-pressing process to form a flexible and breathable composite structure. Even pressure (0.4-0.8MPa) must be applied during heat sealing to prevent air bubbles or adhesive leakage.

2. Process Advantages and Functional Adaptability

Durability: The sweat-resistant properties of TPU hot melt adhesive extend the product's lifespan.

Comfort: The heat-sealed airbags mimic the kneading techniques of human hands, combined with a 42℃ constant temperature heat therapy function, to achieve deep muscle relaxation.

The TPU heat-sealing process is one of the core manufacturing technologies of the hand massager, mainly used for sealing and molding the airbag structure to ensure the product's durability and comfort. The following are specific technical details:

1. Core Parameters of the TPU Heat-Sealing Process

Temperature Control: A precise temperature control range of 110℃-140℃ is used, achieving ±0.5℃ stability through heating elements and a temperature control chip to prevent overheating or poor adhesion.

Pressure and Time: The heat-sealing pressure is 0.4-0.8MPa, and the single heat-sealing time is controlled within 5-15 seconds to ensure that the lamination adhesion strength between the TPU film and the inner liner exceeds 8N/mm.

2. **Technological Advantages:**

Environmentally Friendly: No solvent-based adhesives are used, fully compliant with FDA certification, avoiding VOC pollution, and has passed extreme environmental testing from -40℃ to 130℃.

Airtightness: The heat-sealed airbags can withstand 100,000 bending tests, ensuring no air leakage during inflation and deflation cycles.

3. **Functional Adaptability:**

**Separate Finger Design:** The heat-sealing process achieves independent sealing of 8 airbags, supporting differentiated massage needs for fingers, palms, and wrists.

**Heat Therapy Function:** The heat-sealed layer combined with a 42℃ constant-temperature heat therapy system promotes blood circulation while maintaining uniform temperature distribution.

4. **Industry Comparison:** TPU heat-sealing technology is 80% more efficient than traditional adhesive processes and can handle complex structures (such as the progressive shrinkage design of finger straps), meeting the needs of 3D kneading functions.