Balloon catheter materials and heat sealing process

Balloon Catheter Materials

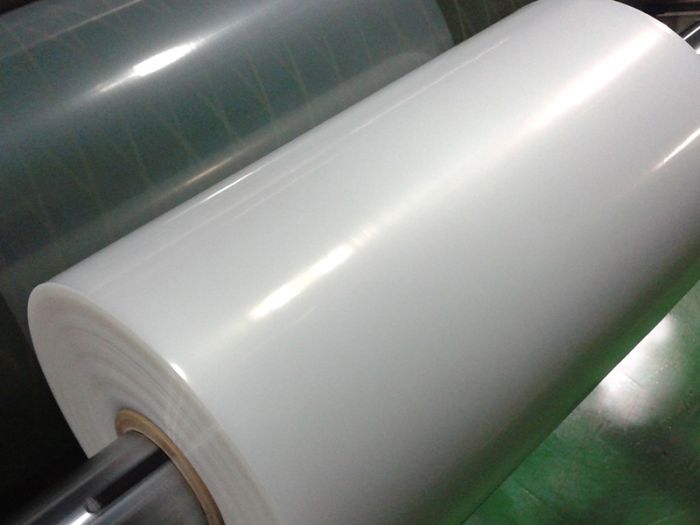

Balloon Materials:

Common materials include polyurethane (PU), polyethylene (PE), polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE) and its alloys, and polyester (PET). These materials exhibit high strength, non-expandability, thermal stability, chemical stability, and sterilizability. For example, balloons used in angioplasty must have controllable dimensions to prevent overexpansion and artery damage or rupture.

Catheter Materials:

The outer layer is made of polyurethane, while the inner layer uses Pebax. Alternatively, the catheter shaft may be constructed from radiopaque nylon 12 copolymer with a hydrophilic coating. Pebax 7033 is also occasionally employed.

Other Component Materials:

- Insertion sleeve: Pebax

- Probe: Stainless steel

- Y-connector: Polyvinyl chloride (PVC)

- Catheter hub: Polyurethane

- Balloon lumen connector: Polycarbonate

- Radiopaque markers: Platinum-iridium alloy (10% iridium)

Balloon Catheter Thermal Bonding Process

Purpose of Thermal Bonding:

To securely bond the balloon and catheter into a complete balloon catheter product.

Key Process Steps:

-

Preheating Treatment:

- The welding area of the medical balloon catheter undergoes preheating to enhance fusion quality and sealing.

- Preheating temperature: 250–400°C (varies based on material and thickness).

-

Welding Methods:

- Commonly used equipment includes the Puxiong Medical Thermal Welding Machine, which offers advantages such as minimal deformation, high bonding strength, and efficiency, making it widely adopted in balloon catheter manufacturing.

-

Post-heat Treatment:

- Post-weld heat treatment is applied to eliminate residual stress in the bonded area.

High-Frequency Welding Machine Applications

Advantages:

- Energy efficiency: Over 50% energy savings compared to traditional resistance welding.

- Rapid heating: High-frequency currents (up to several kHz) enable instant heating to target temperatures.

- Compact design: Lightweight and adaptable to confined spaces.

- Precision control: Customizable parameters (e.g., heating rate, dwell time) for diverse materials.

- Eco-friendly: No emissions of waste gas or wastewater.

Performance in Manufacturing:

High-frequency welding machines improve production efficiency, ensure weld quality, reduce energy costs, and minimize labor intensity in medical balloon catheter fabrication.