Liquid bag welding forming + synchronous cutting process

Liquid bag welding, forming, and synchronous cutting processes are core steps in liquid bag production. Enabled by automation, they deliver efficient and precise manufacturing, widely used for liquid packaging in food, chemical, agricultural, and other industries. Below is a detailed explanation of the process principles, technical advantages, and key equipment components:

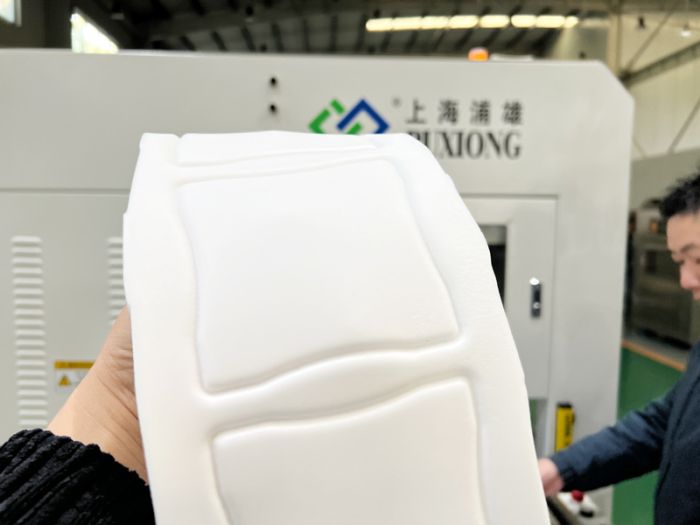

.jpg)

I. Process Principles

1. Liquid Bag Welding and Forming

- Material Selection:

High-strength, corrosion-resistant composite films (e.g., PE/PA/PE, PET/AL/PE) are used, with barrier layers selected based on liquid properties. - Welding Methods:

- Thermal Welding: Heating plates or high-frequency electromagnetic waves melt film layers, forming sealed welds under pressure.

- Forming Process:

Film is unwound via guide rollers, and welding modules create sealed structures at preset positions (e.g., sides, bottom).- Critical Parameters: Temperature, pressure, and time are adjusted based on material properties to ensure weld strength ≥80% of the base material.

2. Synchronous Cutting

- Timing: Cutting occurs post-welding but before the liquid bag fully exits the production line, triggered by sensors detecting weld positions.

- Cutting Methods:

- Heated Blade Cutting: A heated blade slices the film while sealing edges to prevent delamination.

- Cold Blade Cutting: High-pressure air or vacuum-assisted cutting achieves precision without thermal distortion.

- Accuracy Control: Servo motors drive cutting blades, paired with vision positioning systems, ensuring dimensional tolerance ≤±0.5 mm.

II. Technical Advantages

- High Efficiency

- Welding and cutting synchronized, eliminating intermediate steps; production speed reaches 30–50 units/minute (size-dependent).

- High automation minimizes manual intervention, reducing labor costs.

- Consistent Quality

- Digitally controlled welding parameters prevent defects like weak or incomplete welds.

- Synchronized cutting ensures dimensional uniformity, improving downstream filling efficiency.

- Material Savings

- Precise cutting reduces edge waste, increasing material utilization by 10%–15%.

- Customizable composite films (layer count, thickness) lower raw material costs.

- Versatility

- Compatible with diverse capacities (1L–25m³) and shapes (square, cylindrical, custom).

- Rapid mold swaps enable flexible multi-specification production.

III. Key Equipment Components

- Unwinding System

- Dual-station unwinding racks enable automatic roll changes for continuous operation.

- Tension controllers prevent film stretching or deformation.

- Welding Module

- Thermal or ultrasonic welders with adjustable heating plates/transducers.

- Custom molds for specific bag shapes, supporting quick replacement.

- Synchronous Cutting Unit

- Servo-driven rotary/linear blades with pneumatic clamping.

- Integrated vision systems correct cutting position deviations in real time.

- Winding/Stacking System

- Automatic winders roll finished bags into筒状 (cylinders) or robotic arms stack them onto pallets.

- Equipped with counting and sorting for smart packaging.