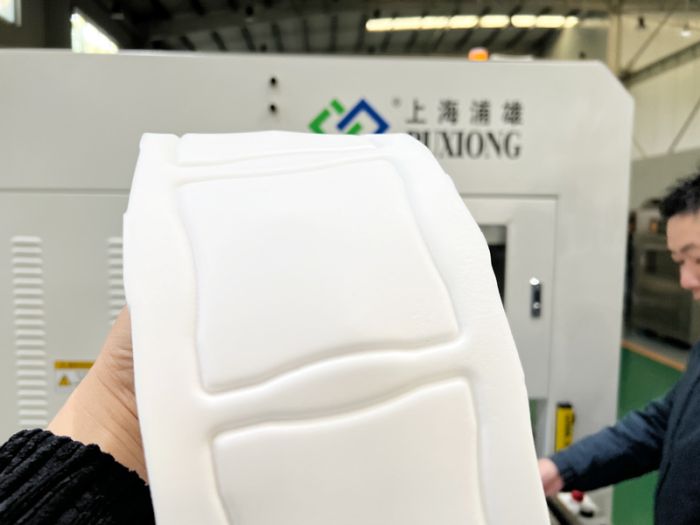

Heat sealing and welding of airbags for hand massage devices

For the thermal fusion welding process of TPU airbags in hand massagers, integrating medical-grade material properties and industrial application experience, the following key solutions are proposed:

.jpg)

I. Material Selection & Pre-treatment

- Medical-grade TPU Film

- Recommend medical TPU material with Shore hardness 85A-95A

- Tensile strength ≥40 MPa, elongation at break ≥500% to ensure structural integrity during inflation/deflation cycles

- Surface Preparation

- Clean TPU film surface with isopropyl alcohol before welding to remove mold release agents

- Optional plasma treatment (300W power, 30s duration) to enhance surface energy

II. Welding Process Parameters

- High-Frequency Welding

- Use 27.12 MHz equipment with 0.3-0.5 MPa electrode pressure

- 3-5 second welding duration for bubble-free continuous seams

- Ultrasonic Welding

- 20 kHz frequency with amplitude controlled at 50-70 μm

- 2-3 second holding time for 0.2-0.5 mm thick TPU films

- Temperature Control

- Maintain mold temperature at 80-100°C during HF welding to prevent thermal degradation

III. Quality Control Standards

- Air-Tightness Testing

- 0.5 MPa pressure holding test (≥30s duration)

- Leakage rate <5 ml/min

- Peel Strength

- Weld seam peel strength ≥8 N/cm (tested per ASTM D1876)

IV. Process Optimization Recommendations

- Mold Design

- Implement split mold structure

- Control core-cavity clearance at 0.02-0.05 mm to prevent material extrusion

- Environmental Compliance

- Minimize harmful emissions through eco-friendly materials and processes

Note: Conduct Design of Experiments (DOE) in production to optimize parameter combinations, particularly balancing weld strength and sealing performance.